Pulp & Paper

Panjapol Fibre Container

Pain Point/Need:

Inspection and maintenance work for boiler during plant shut down.

Action:

EPS conducted an inspection, repair and set the alignment for Whirl screen and also improve the Rotary screen chute by install the protection plate at wear point.

Result:

Provide maintenance work within shutdown schedule and budget also improve the lifetime of the machine

Pain Point/Need:

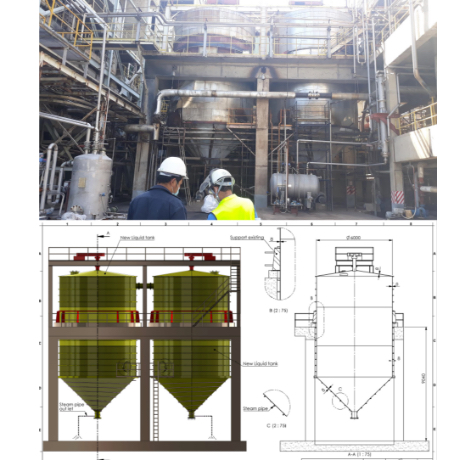

Customer need to fabricate the liquid tank which is in operation for more than 25 years. The tank wall thickness wear down to 3.5 millimeter from its original 8 millimeter. However, the difficulties in this job is that customer does not have original drawing and still doubt the quality of EPS fabrication.

Action:

EPS invited customer to visit our workshop at Kaeng Khoi to make their confidences while we introduced them to our working process and quality control.

Result:

Customer were convinced by the quality that EPS can provide. The liquid tank fabrication were handle professionally.

Panjapol Pulp Industry

LINE

LINE