Fertilizer

Thai Central Chemical Company

Pain Point/Need:

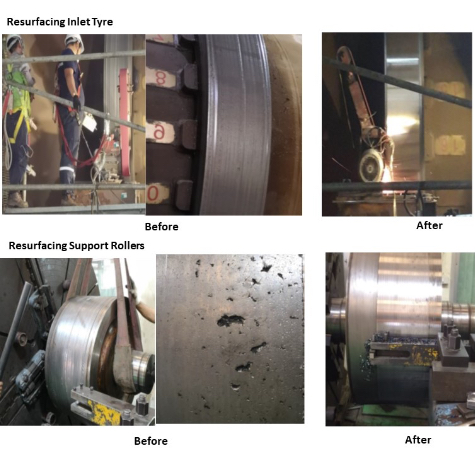

The rotary drum for fertilizer drying process had serious operation problems, i.e. uncontrolled axial movement of rotary drum, more power consumption, vibration, etc.; resulted from the uneven profile of contact surface between tyre and support roller for both inlet and outlet ends

Action:

EPS conducted a full inspection and then resurfaced inlet tyre and support rollers to get rid of diameter difference of inlet tyre and support roller that was largely deviated from standard.

Result:

Bring rotary drum service life back to standard with the acceptable surface condition.

Pain Point/Need:

Customer planned to increase production rate of plant, therefore raw material conveyor need to be expanded.

Action:

Stacking belt was designed and built to support the increasing of the customer production capacity effectively.

Result:

The project was done on time, on budget, and vertical start-up.

YARA Thailand Co., Ltd.

Terrago

Pain Point/Need:

Roller's shell cracked, roller's bearing brokedown, and high vibration in girthgear. Customer need to repair and find the causes of problems.

Action:

EPS sent specialist team to do full-inpection of machine conditions to find root causes of problems which can be summarized as below:

- Lifetime of roller's shell and bearing was short because dryer and cooler shell were erode in higher rate than control point and migration value of machine is higher than standard. Our solutions are fracture repairing and shim shoe installation to reduce migration and shell ovality, including planing for shell overhaul.

- Girth gear and pinion teeths are wored down. Radial alignment value is high. Our solution is to reverse the gear.

- Adjust axial balance and other conditions to bring it back to acceptable range in standard.

Result:

- Migration value and Shell's ovality are reduced which lessen shell's crack problem.

- Vibration of girth gear is decrease.

- Skewness of roller is normal.

- Machine condition is back to standard design and in normal operation

LINE

LINE